© 2024

Karver Systems | Honfleur, France | 2023

Designed as a contribution to the free3d platform of Karver Systems, a high end french manufacturer of sailing equipment.

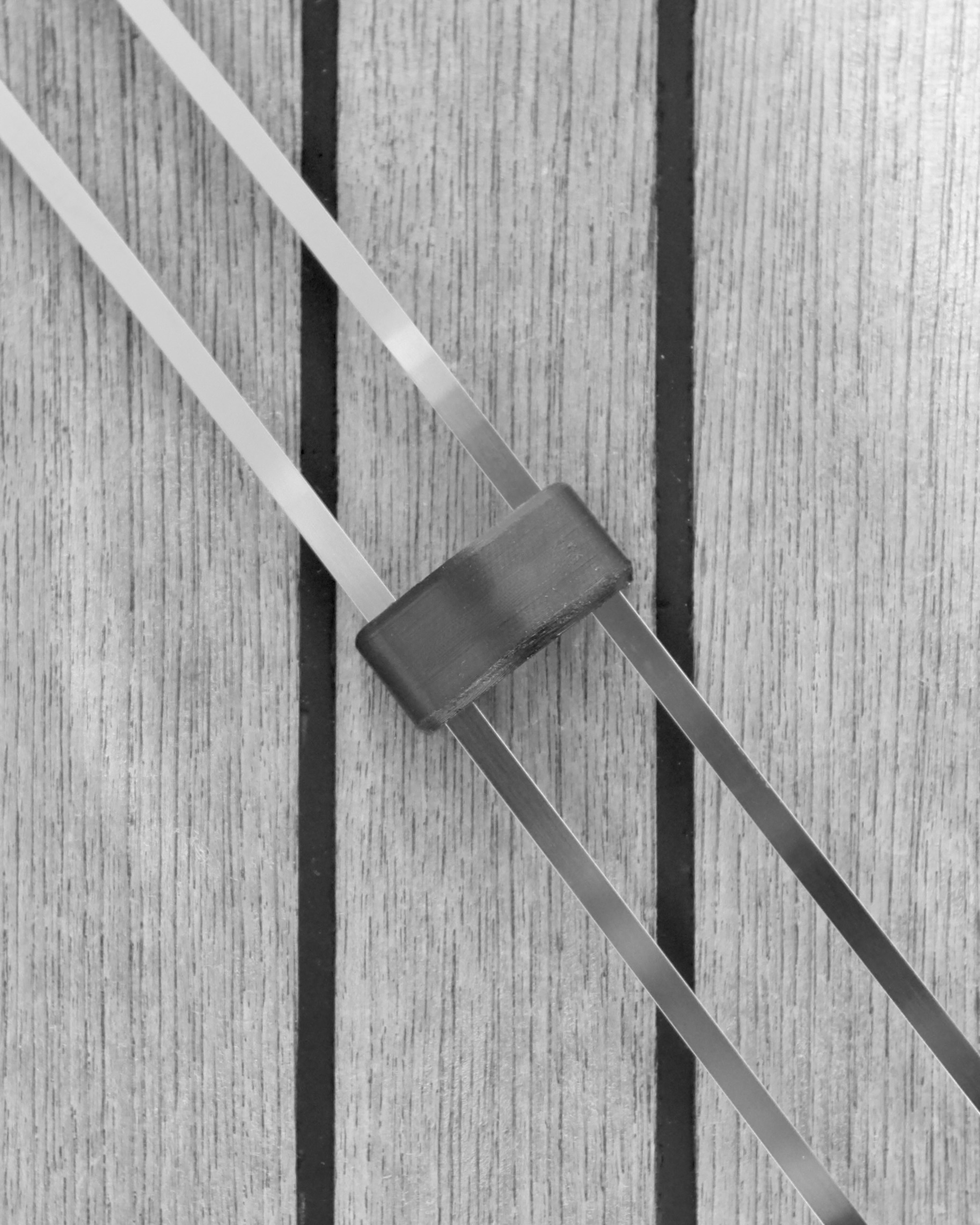

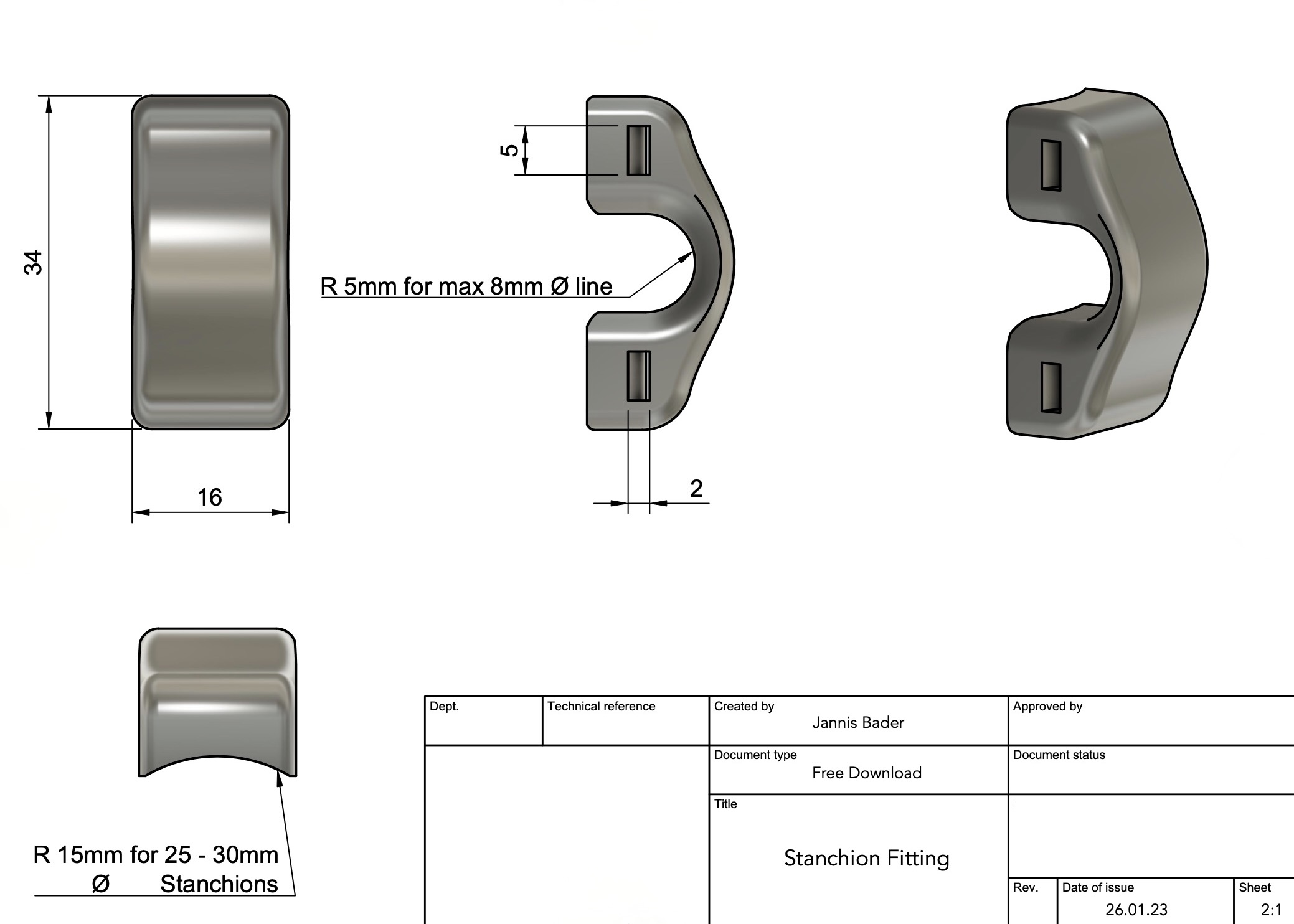

The stanchion fitting can be used to guide a line from the boat’s bow to the aft. Two stainless steel cable ties are used to mount the fitting resulting in no need for drilling or screws. I.e. simpler installation.

The shape is the outcome of multiple design iterations to reduce material usage. Yes 3D printed ABS is recyclable but no need to be superfluous. The positive consequnce is a fitting that weights only 3.2g (excluding the cable ties) and in racing every gram counts.

The STL file and installation instructions can be downloaded via karver-systems.com.

Group project in Biomimicry | Den Haag, The Neatherlands | 2023

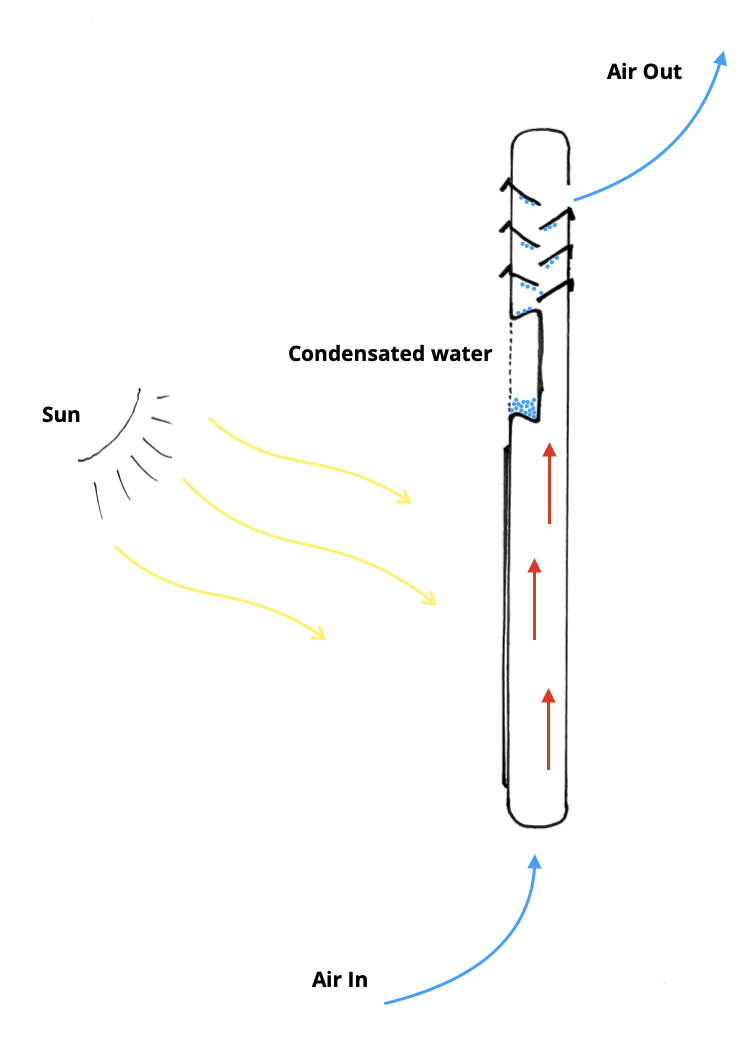

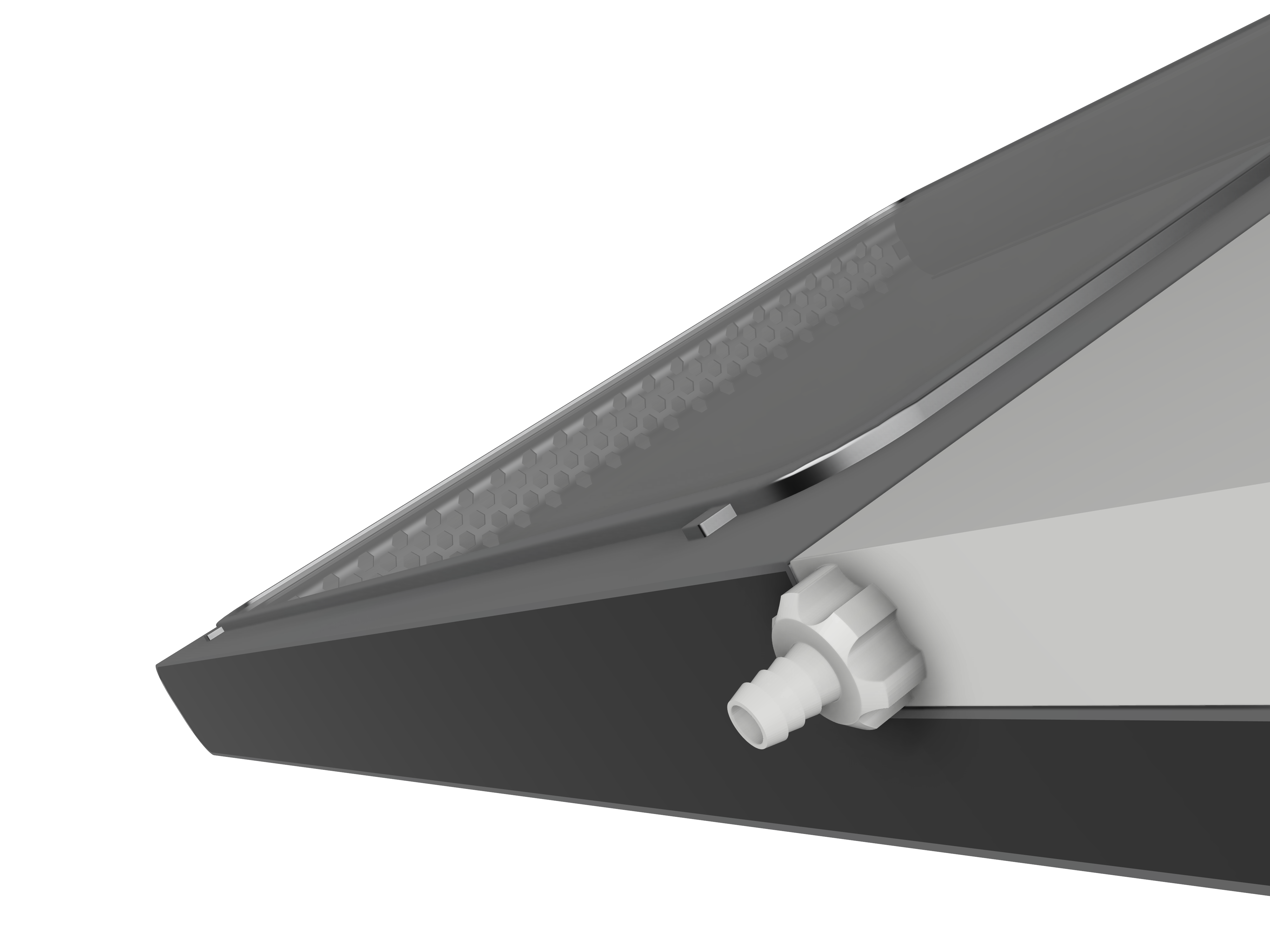

A self-sustaining system for water collection from air moisture. Inspired by the functioning of the bumps on the back of the Namib desert beetle and the air temperature regulating system of a Camel’s nose.

The Namib desert beetle uses the bumps on its back to collect air moisture, which quickly forms into droplets due to the surface structure. It will guide the droplets to the mouth by lowering the forelegs and tilting forward.

Through testing, it was established that a bumpy surface is more efficient at creating water droplets than plain or sanded surfaces.

The Camel uses its nose to create a temperature difference. At night, the cold desert air cools the large nasal surface and warms the body temperature in the lungs, where the warm air then gathers body moisture. Upon breathing out the moisture condensates on the cooler nasal surface, retaining water for the camel in a harsh environment.

Dew Point uses the sun to heat a heating chamber (i.e. the lungs) and the ambient air temperature to keep condensation surfaces cool. The bumps from the Namib desert beetle provide efficient water condensation. Through the rising of the warmer air inside the system, new air is pulled in at the bottom.

In theory, Dew Point could generate up to 4,9L of water per week (depending on the air moisture level) and may act as an addition to established water supply systems to assure water security or access to water in low-resource settings.

Research Group Technology for Healthcare | Banjul, The Gambia | 2024

In The Gambia, more than half of the health system is sustained through foreign aid. More than half of the population live below the country’s poverty line of 1503 Gambian Dalasi per month (22.13 USD, March 2024). Traditional treatment methods are often preferred over the visit to a more expensive western hospital.

The main causes of mobility impairment are poliomyelitis, malformation by birth and failure in traditional medicine to heal a broken leg resulting in amputation.

Donated mobility devices such as crutches and wheelchairs are designed for the Western context and do not function well on sand. Furthermore, maintenance and sourcing spare parts in a low-resource setting is a strain for those in need.

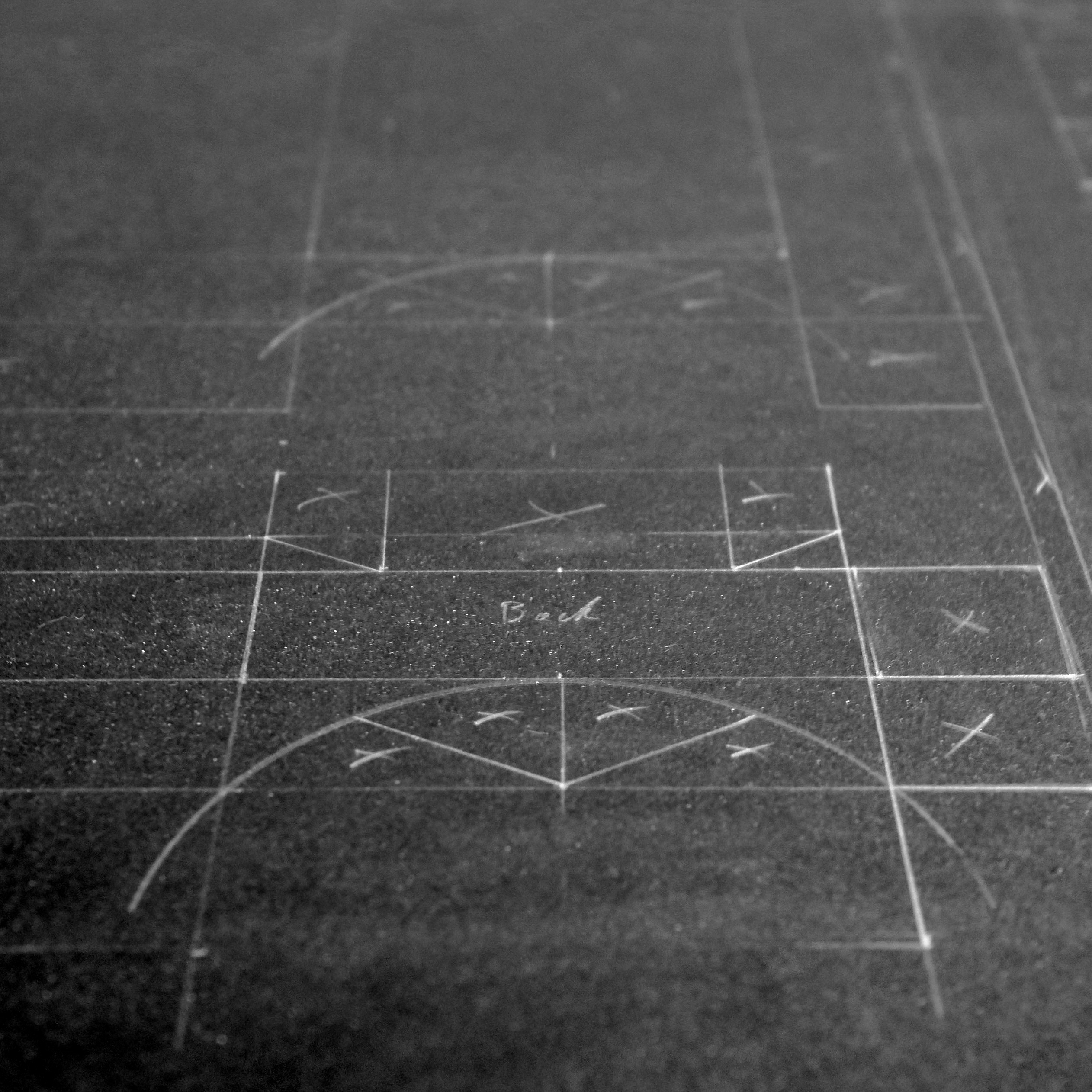

During a four-week long research visit to Banjul and Base hosted by the Medical Research Council Unit of the London School of Hygiene and Tropical Medicine (MRC) and financed by the Research Group Technology for Healthcare of The Hague University of Applied Sciences, research was done to gain insights for the design of locally manufacturable mobility devices. Two Co-design sessions, the first with leaders of local disability organisations, the second with a group of women bound to a pushpush (gambian slang for wheelchair), resulted in cardboard prototypes and material suggestions. Furthermore, to see mobility as an issue between the house door and a form of public transport - tuktuk, taxi or collective town trip bus.

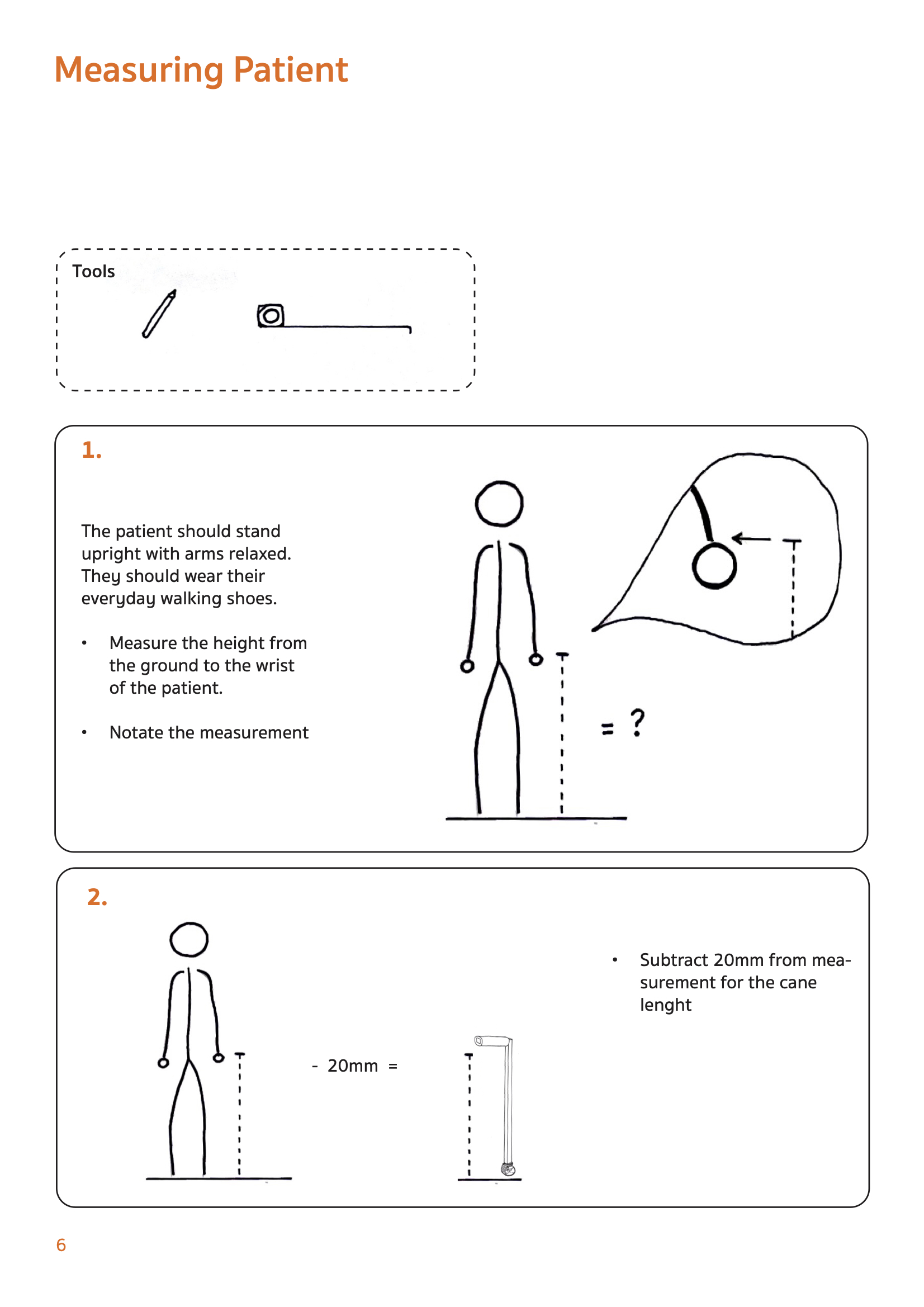

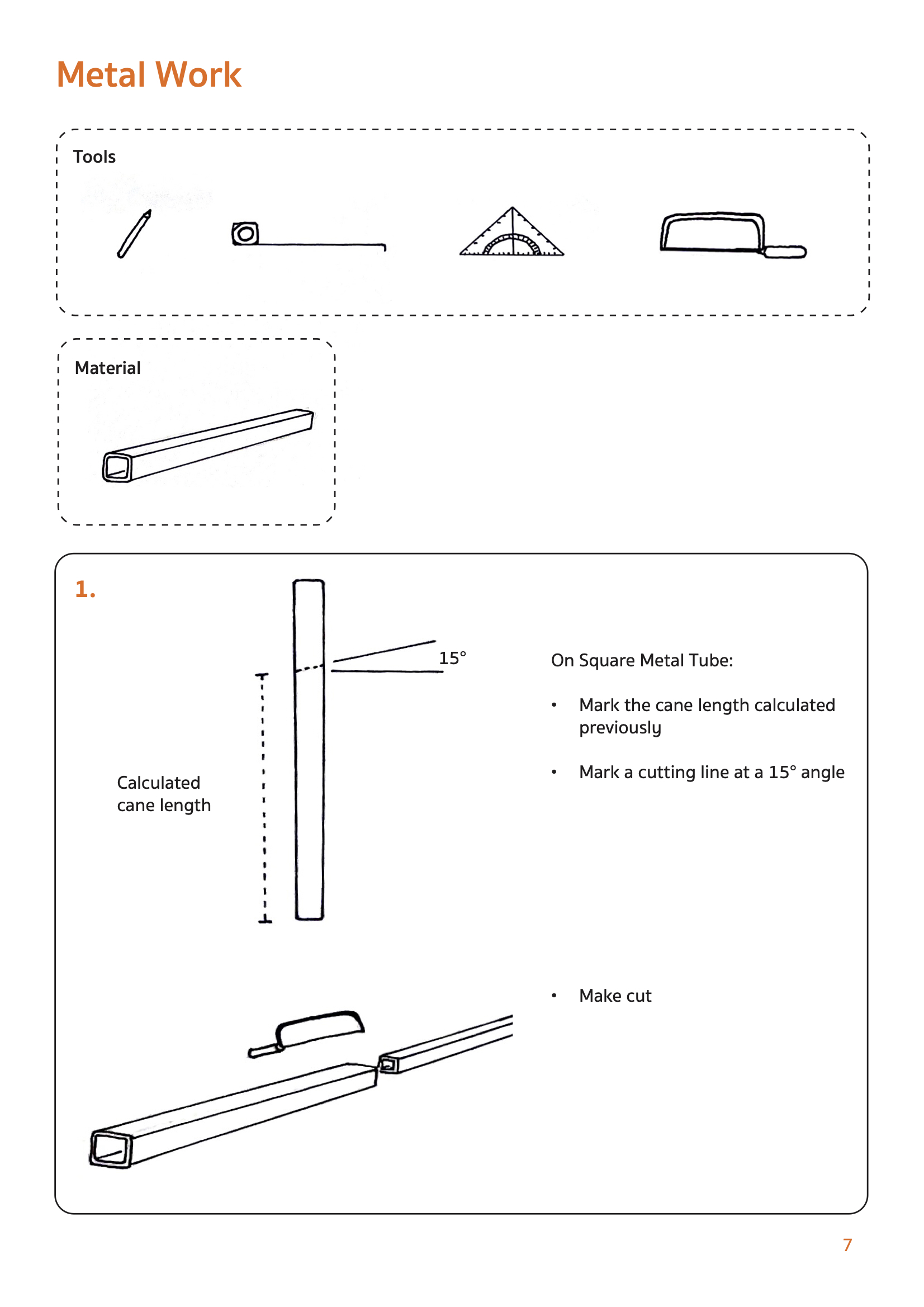

The design of a modular walking cane and crutch is based on the widely available skill of welding and locally available materials so that persons with mobility impairment can create for themselves what serves them.

°Leg, handle, arm support, cuff

2x20x20mm square metal tube

°Handle material

Upcycled PET formed through heat moulding

°Foot

Two self-locking stripes of car tyre. Flexible in the joint like the human foot, and spreads out to manage sand better like the foot of the camel. The foot design provides a substantial grip.

°Manufacturing Instructions

Standard A4 print (Internet is not widely available). Sketched to accommodate for illiteracy.

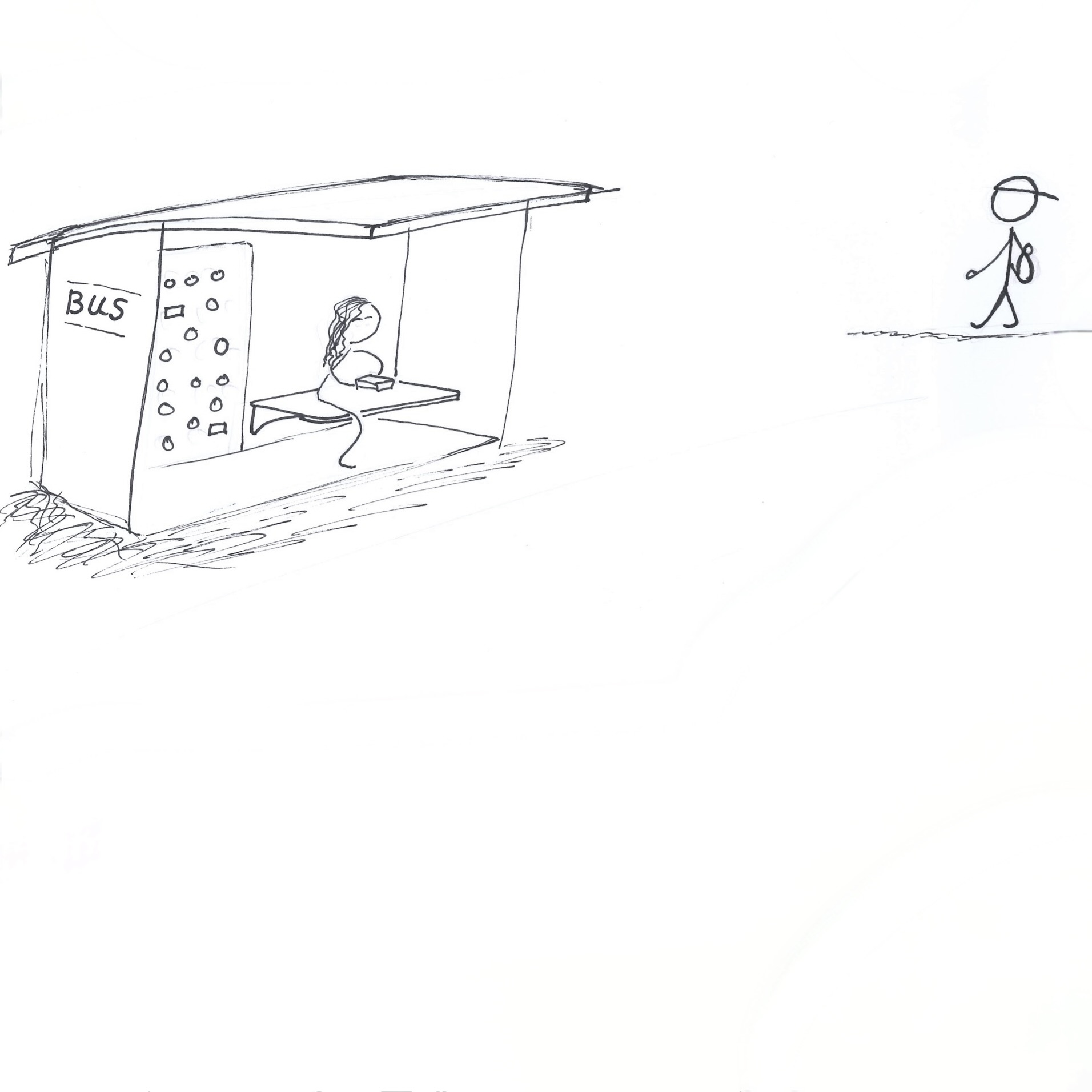

Group project for Hola Studios | Rotterdam, The Neatherlands | 2023

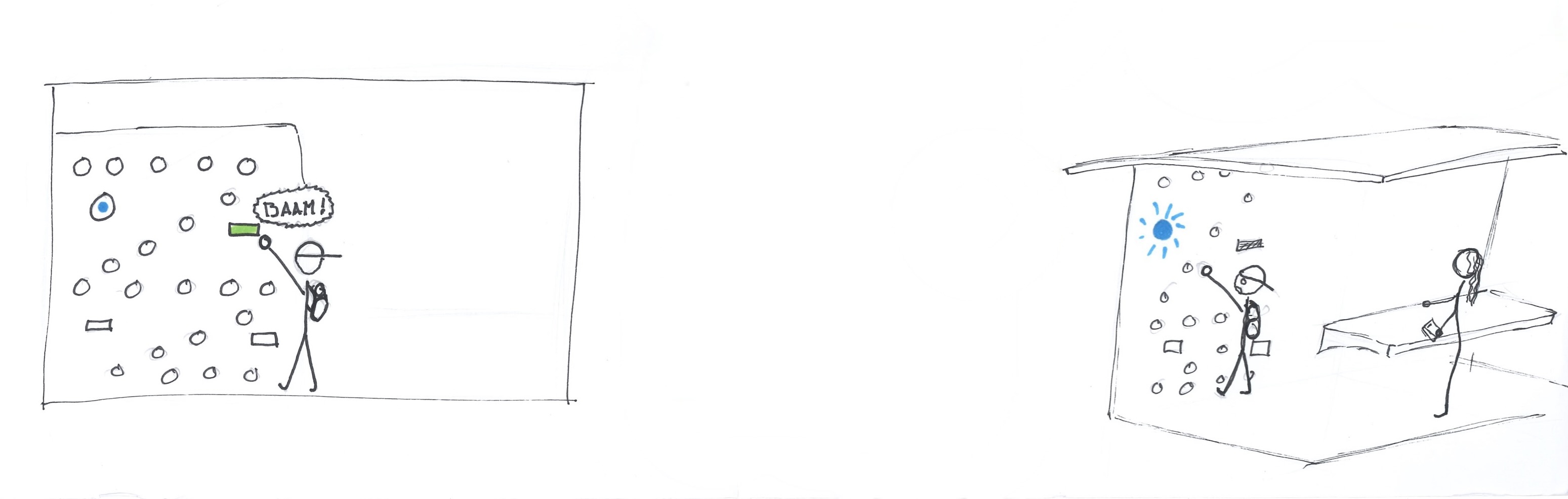

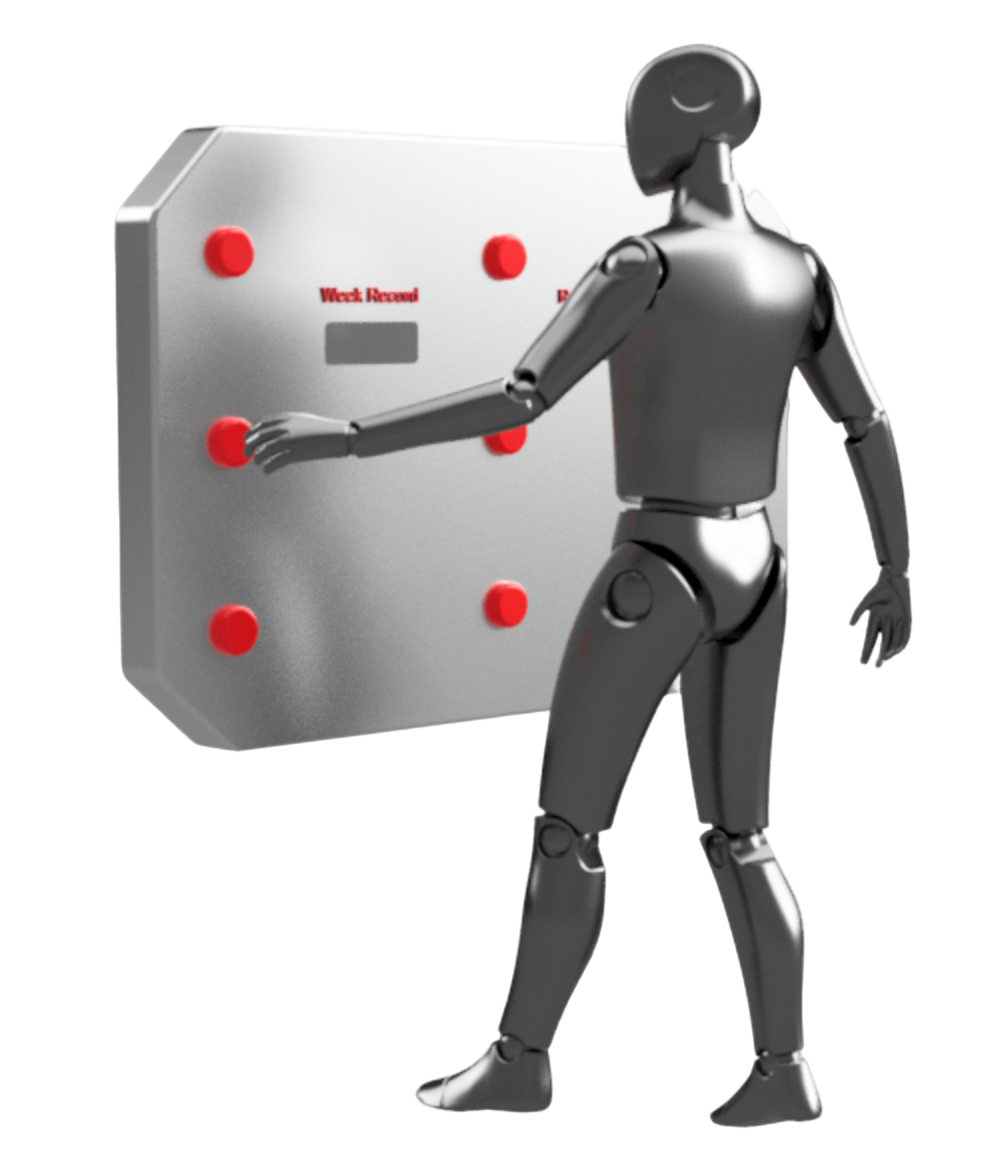

Yorrit is walking by the bus stop as he notices a light pop up beside Coco. Coco is on her phone and does not see the light. Yorrit hits the light. It turns off. And the next light turns on. This one is out of his reach, and Yorrit is distressed. Coco notices Yorrit playing with the light on the board and stands up. She is taller than him and hits the light off. Together, they complete the game on Arcå.

The brief for this project was to create a light installation that incites movement. The World Health Organisation called to create movement opportunities in the public space to better the physical health of young adults (and reduce screen time).

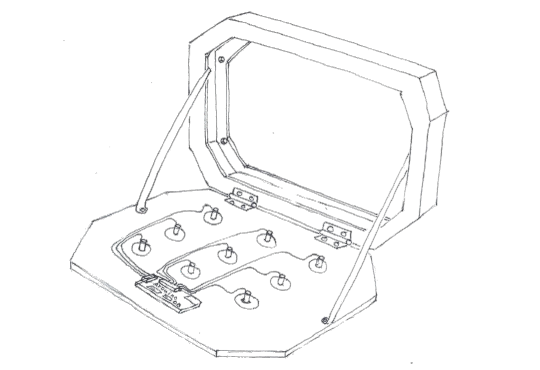

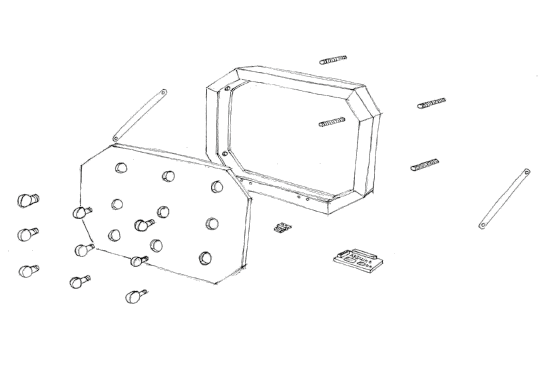

The prototype was made from wood, arcade buttons and an Arduino Mega to collect engagement data and user feedback. Arcå was on display during ThingsCon 2023 at Het Nieuweinstituut in Rotterdam.

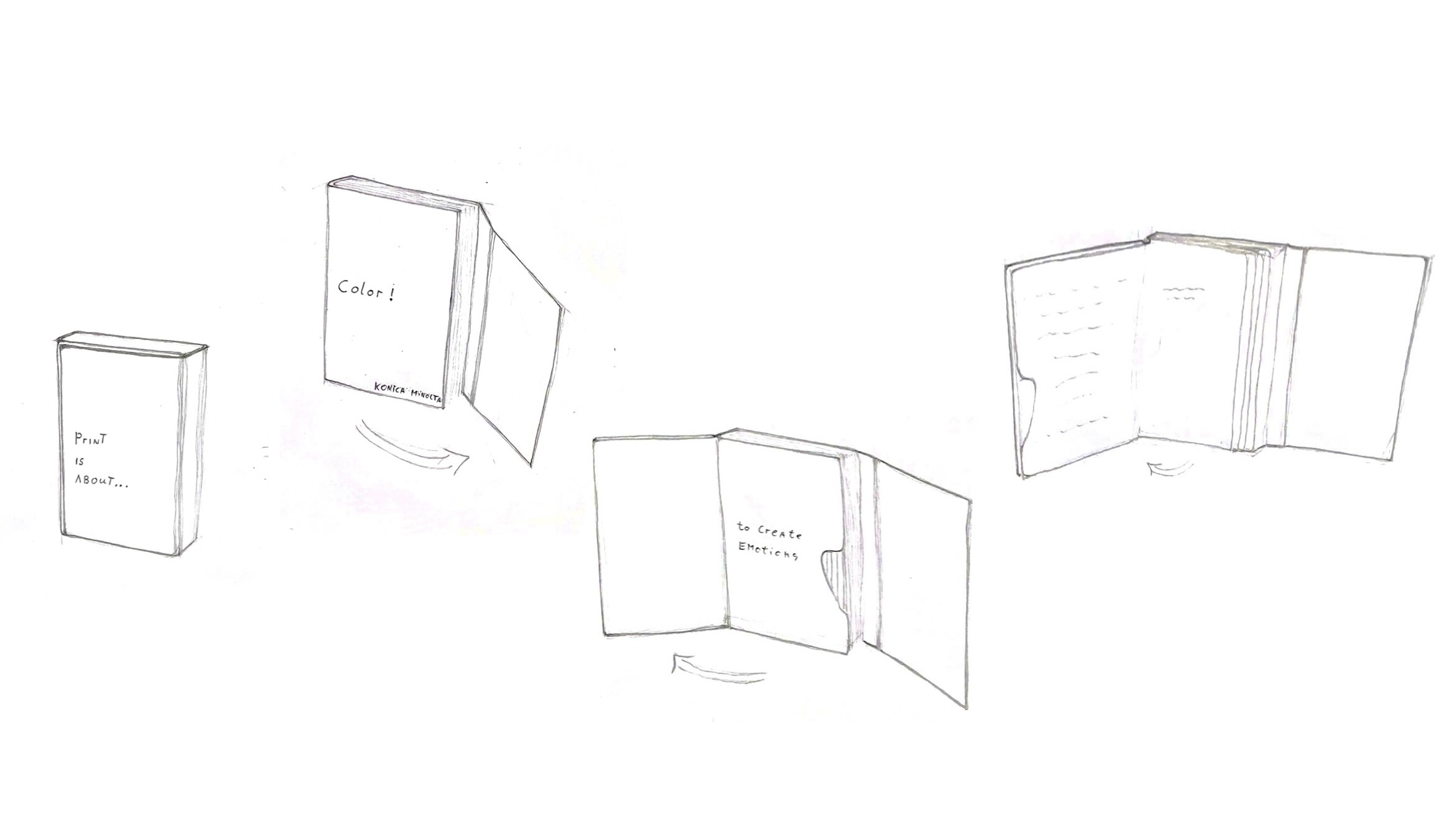

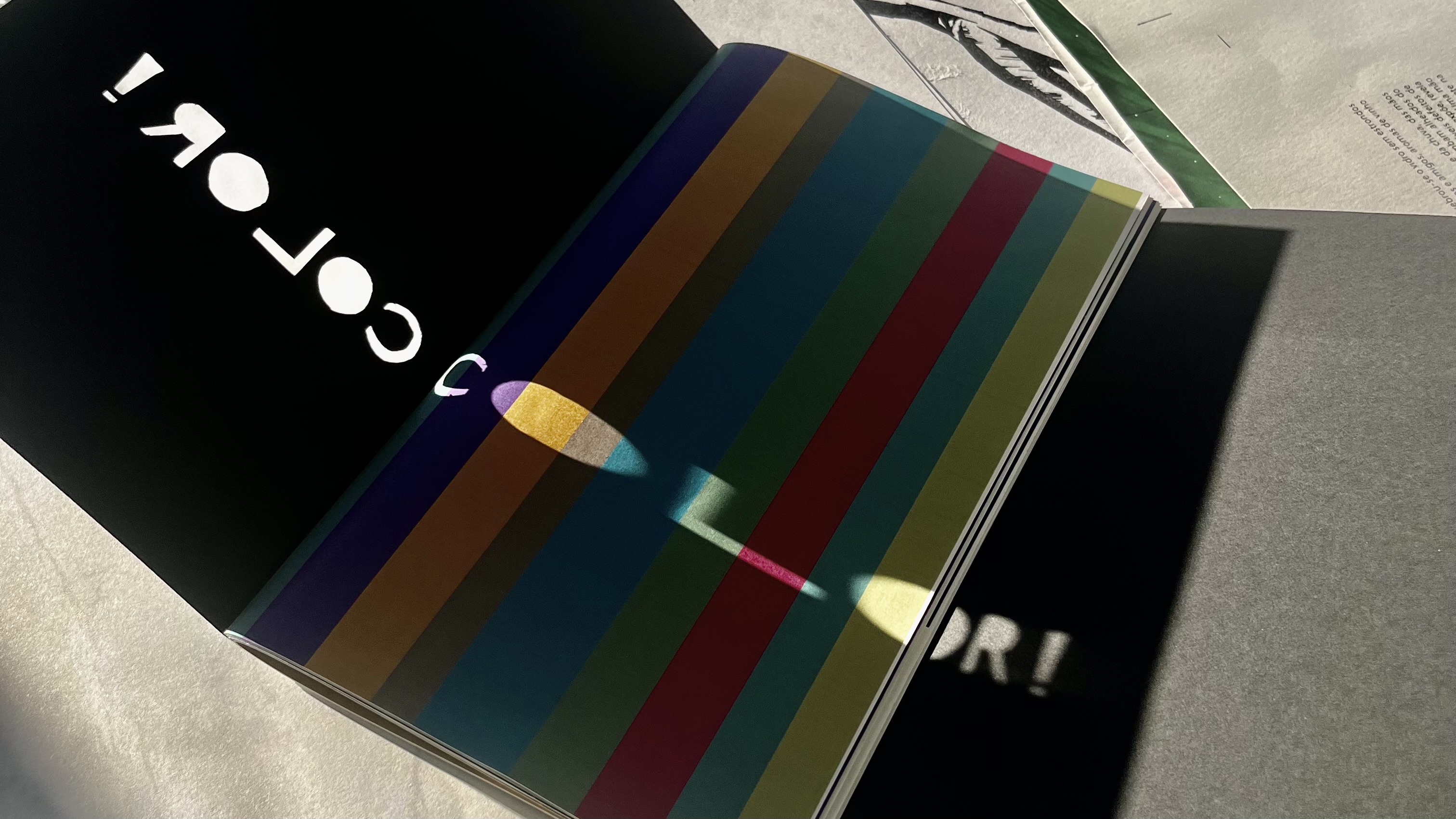

Group project for Konica Minolta | Lisbon, Portugal | 2024

A concept for Konica Minolta Portugal to showcase the possibilities of their professional printing machines.

The goal was to appeal both to the older and younger generation of business owners. To combine both the traditional and the modern.

Print is about… was one of five nominees to be printed and manufactured.

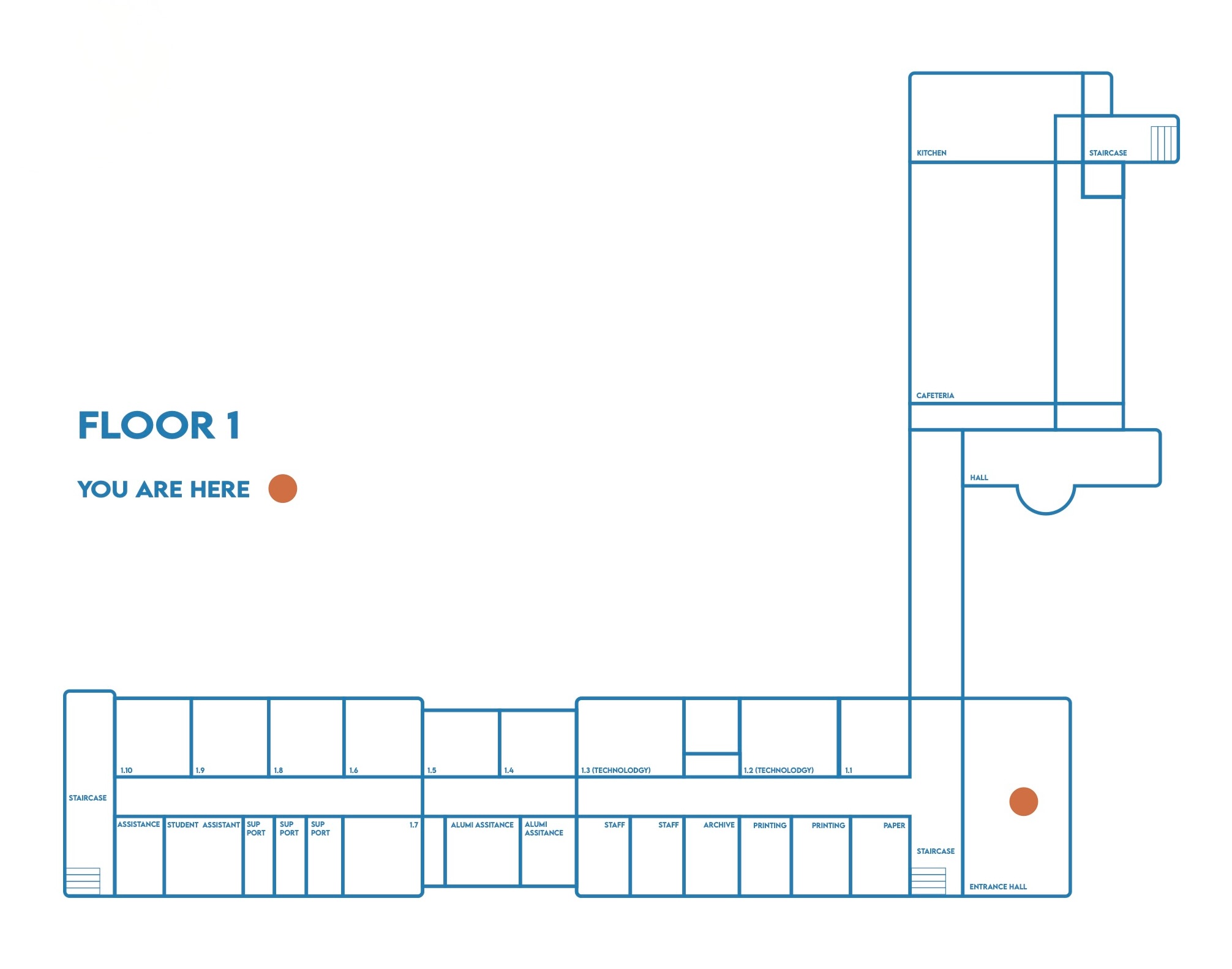

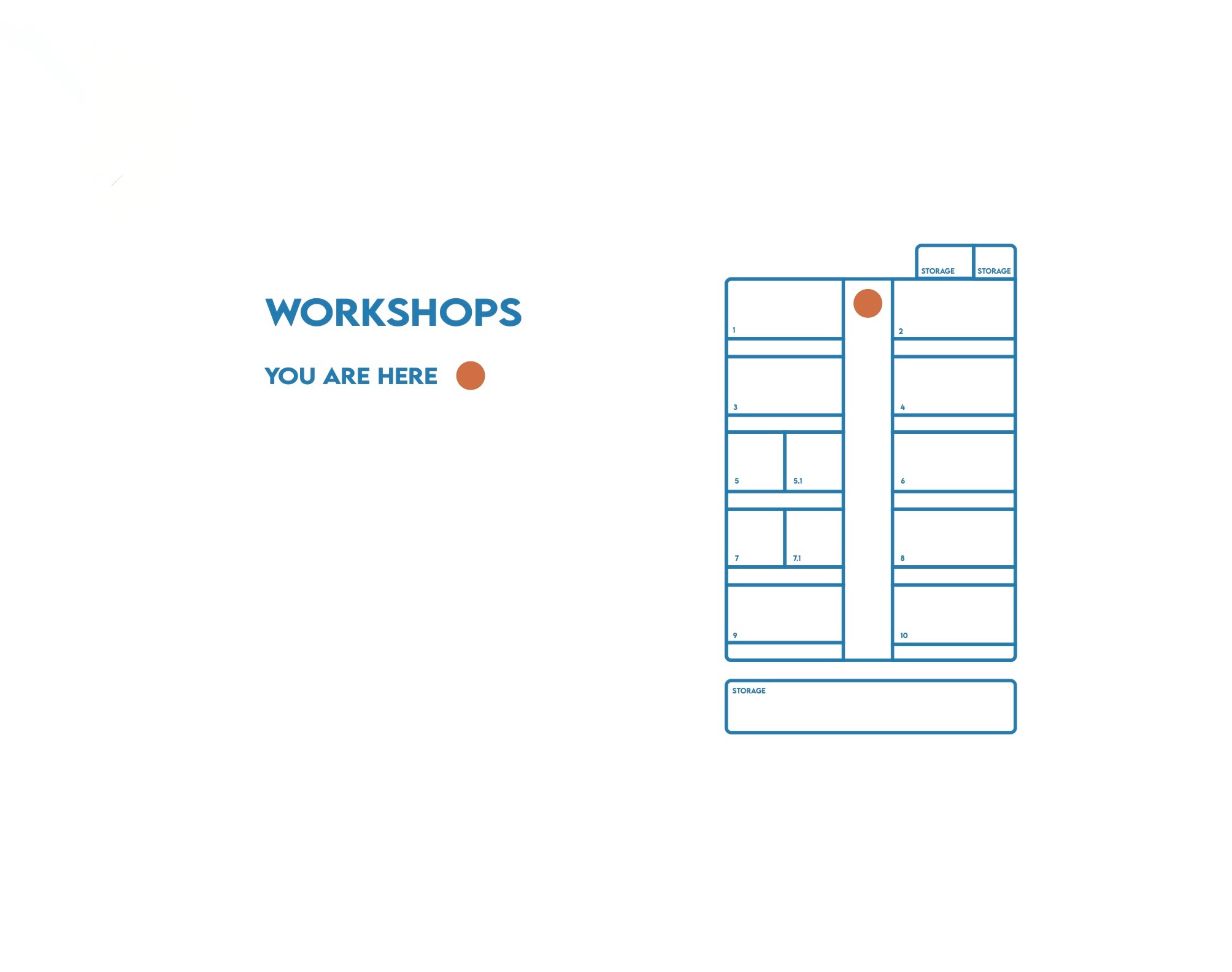

Group project in rebranding and wayfinding for ESMP | Belém, Portugal | 2024

Escola Secundária Marqês de Pombal (ESMP) is a secondary school in Belém, Lisboa with over 140 years of teaching history. Initially a school of industrial design, then a model school during the Portuguese dictatorship, ESMP houses artworks and sculptures of Leopoldo Battistini and a library known by many in front of Portuguese televisions.

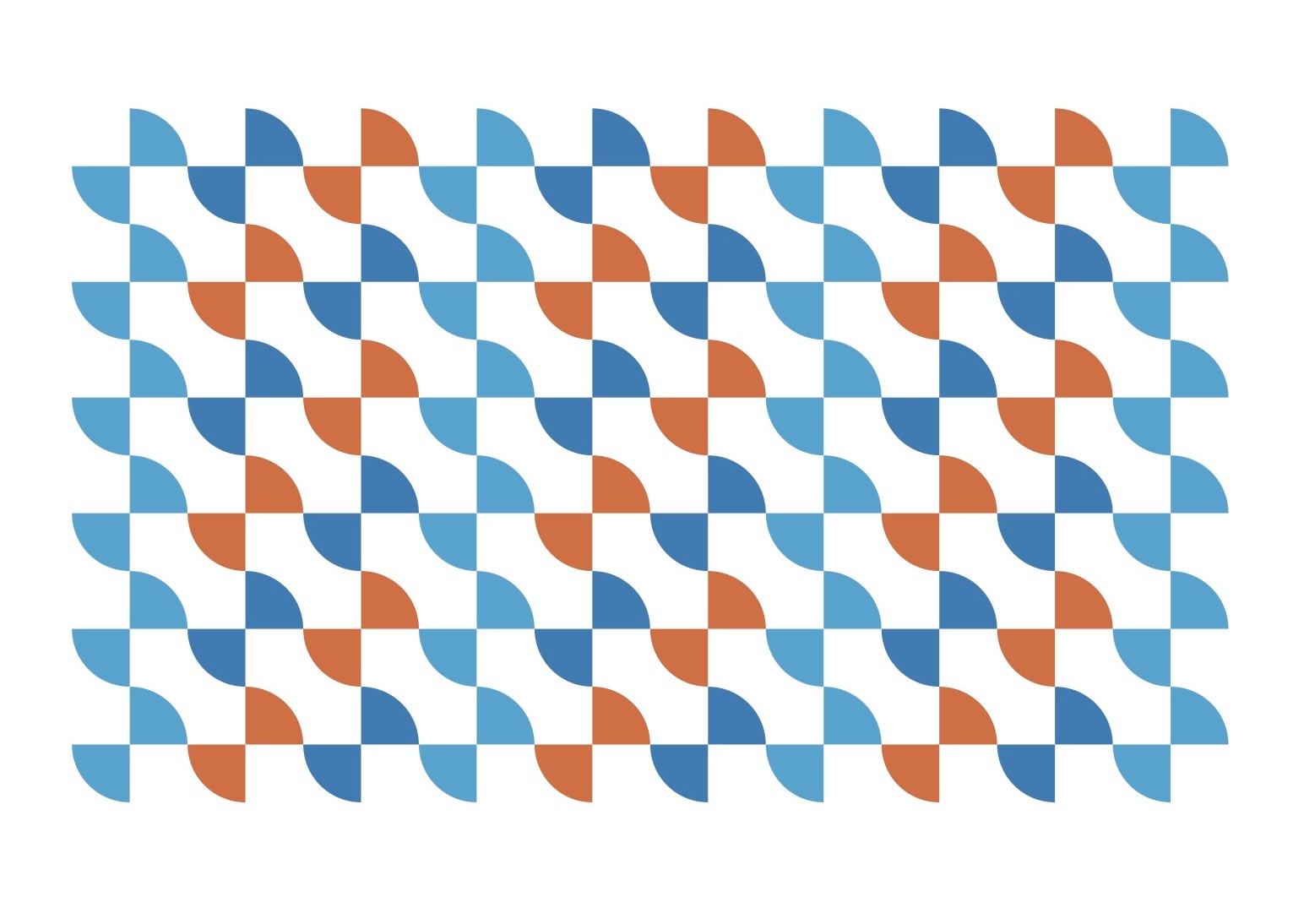

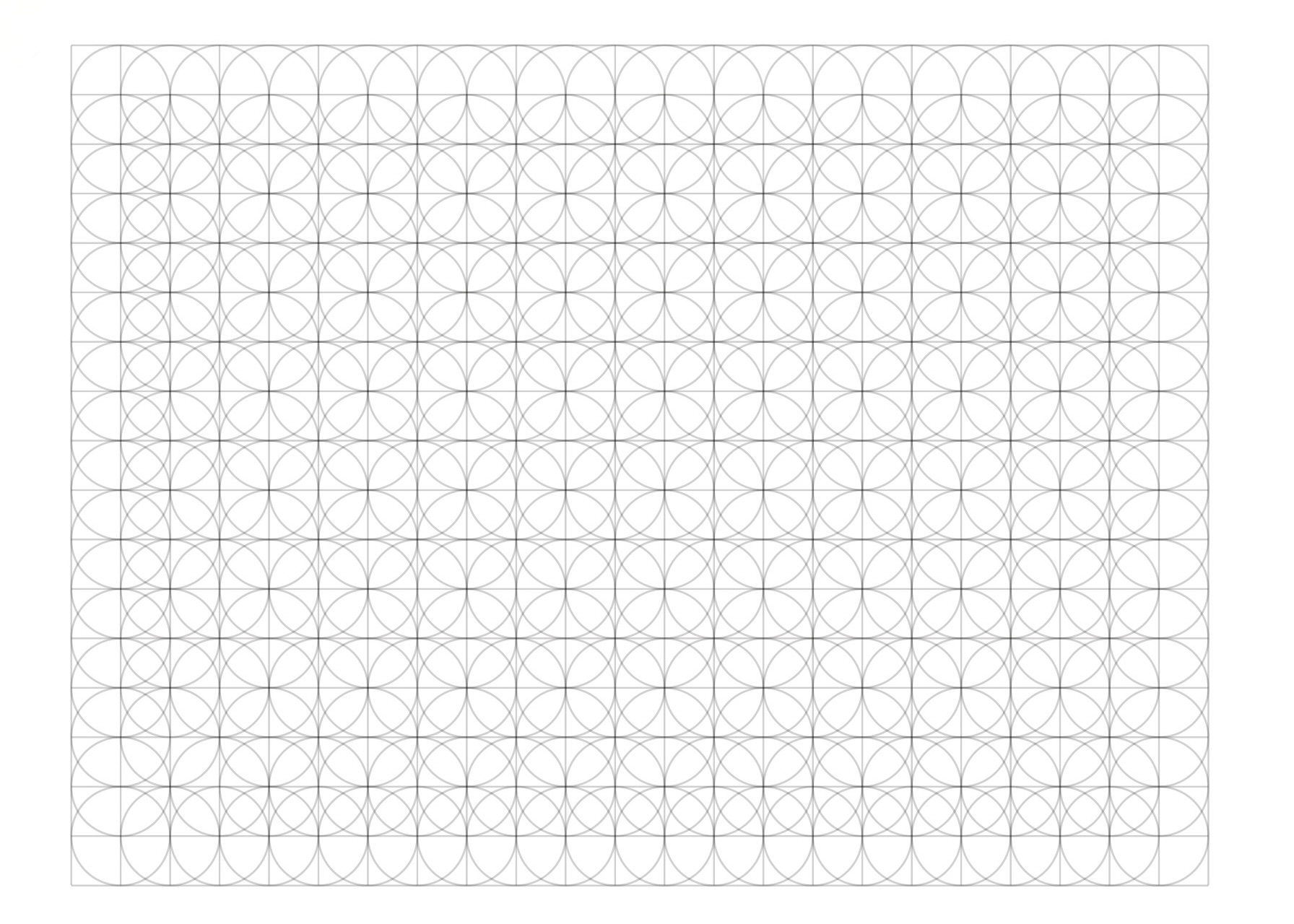

The rebranding and wayfinding for ESMP are based on a circle and a straight line - elements recurringly observed in the school’s architecture.

Starting with defining a grid and colors for a flexible visual system, patterns, a custom logo font and a new wayfinding system was developed for ESMP.

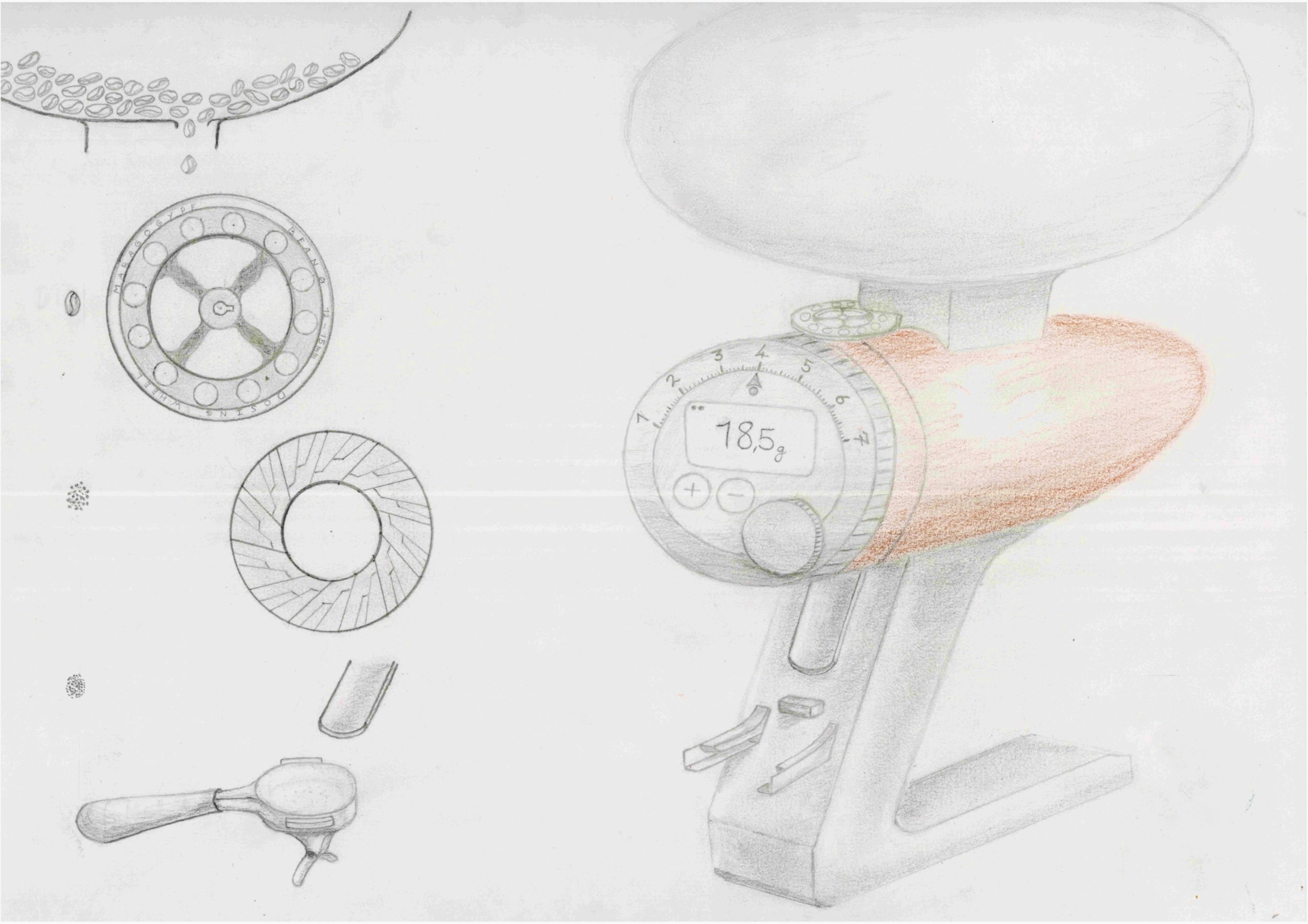

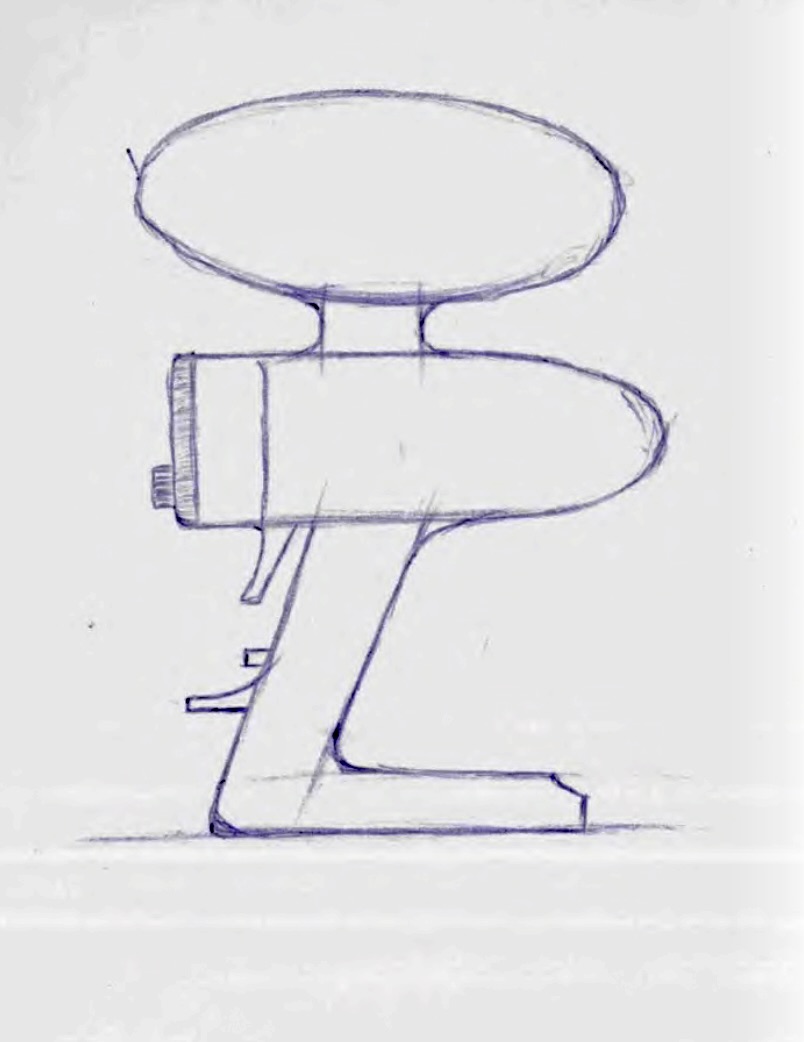

Commercial coffeegrinder concept | 2019

Each bean is hand picked. Often under tiering conditions on a farm more than 1200m above sea level. Dayworkers carrying kilos of produce on their shoulders to the washing station.

A guiding principle in speciality coffee is honouring the farmer’s work through carefully crafted roasting profiles and adapting brewing recipes to best represent the terroir of their coffee. Yet modern grinders waste 18g to 36g of coffee each morning during calibration due to having to purge the grinder when changing the grind size.

Spaceship reimagines the calibration procedure by using a dosing-wheel to measure the quantity of coffee pre grind. Thus saving multiple kilos worth over a year.

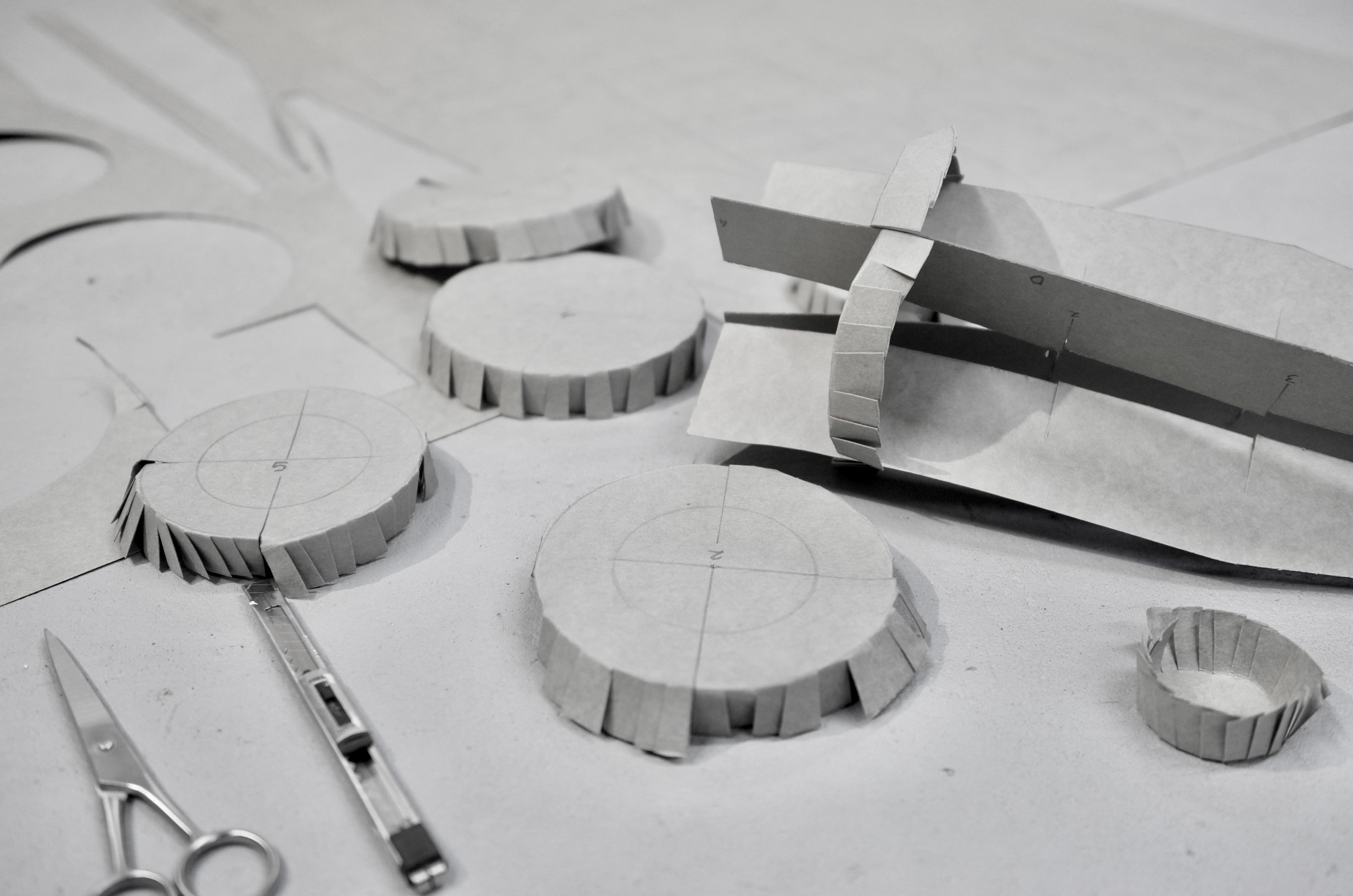

Prototype made from cardboard paper to test for ergonomics and one handed operation.